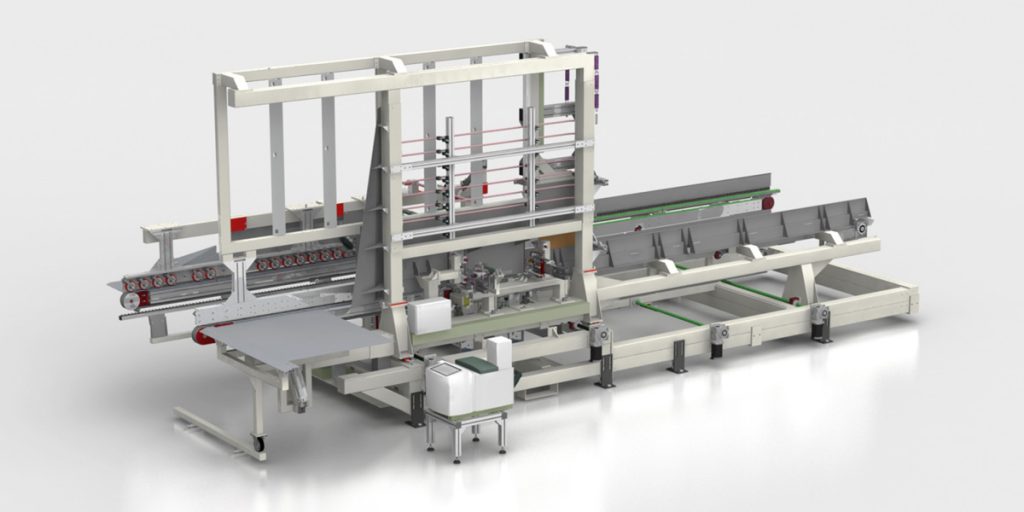

This line has been designed for erecting boxes Mod. FEFCO410. The longitudinal flaps are folded within the first station while the transversal ones (2) are glued and folded with hot-melt glue in order to form the basic “tray” within the second station.

The box dimensions introduced into the line, can be

detected automatically “real time”, allowing this machine

to self-dimension automatically, accepting different boxes one after the other.

All the size-changeovers are carried out in automatic way, fast, managed by the PC installed into the electric cabinet.

Technical specifications

| Materials | Box model FEFCO410 |

| Speed | 10 pcs/min until 1400 8 pcs/min from 1401 to 2000 7 pcs/min from 2011 to 2400 6 pcs/min from 2401 to 3000 |

Product dimensions

| Length | min 300 – max 3100 mm |

| Width | min 200 – max 1200 mm |

| Thickness | max 300 mm |

| Cardboard thickness | min 2 – max 7 mm |

Benefits

| High production capacity |

| Fast sizes change |

| Highly compact dimensions |